GRP Moulds

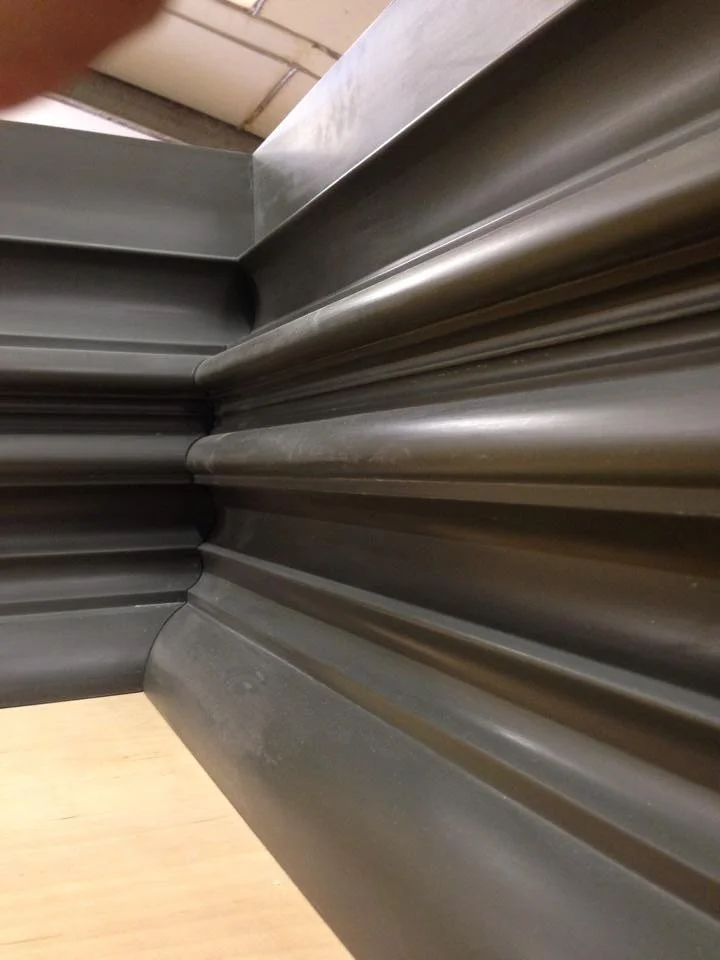

We offer GRP moulds to meet any of your design needs. Manufactured to produce a long-lasting and extremely durable product.

G.R.P stands for glass-reinforced plastic, and the process involves intricate steps that lead to the materials being laid on to a pattern or form in order to take that shape. As you may know, GRP moulds are sought after due to their incredible strength, making them durable and long-lasting.

The majority of projects we have carried out involve using a gel coat and light tissue, which is applied to the pattern, we then apply a further 4 layers of mat and resin which can then have the addition of plywood or steel bonded to aid strength. We also generally use tooling that is manufactured in house by our experienced and dedicated pattern makers.

Our experienced team can deliver your GRP mould to you, and beforehand we will work closely with you to ensure that you receive the GRP mould that fits your specific needs. All of our projects are carried out by our experienced and professional team members at 3D Pattern and Mould Makers.

We have worked on several successful GRP projects, and you can see how our moulds can be utilised in the examples below. In some cases, and where the surface finish on a mould is of paramount importance, the pattern used to form the mould can also be manufactured from GRP, this was the case for the London 2012 project.

Creating GRP moulds is a vastly time-consuming method, which is primarily down to the layering; however, the result it produces is worth the time and effort. In most cases, we aim to get the pattern to a really high standard of finish which in turn transfers to the mould negating the need for any remedial work.

If you have any questions about our GRP moulds, do not hesitate to contact a member of the 3D Pattern and Mould Maker’s team. Our friendly team at 3D Pattern and Mould Maker’s is always on hand to help answer any questions.